Lynn Lake

The Lynn Lake project is located in the historic mining town of Lynn Lake, in northern Manitoba, about 320 km northwest of the Thompson mining camp. The deposit was mined by Sherritt-Gordon from 1953 to 1976 and produced over 20 million tonnes of Ni-Cu, making it the 3rd largest nickel producer in North America. In 1976, during a period of stagnant growth in the nickel market, the mine closed with a significant in-situ nickel and copper resource remaining.

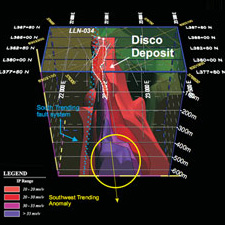

Two additional areas, the Disco and Tango Zones, were defined by Prophecy in 2010 and provide opportunity for expansion of the overall project.

The Lynn Lake project has both electrical power and rail available as well as all-season gravel road access. The mine can be operated year-round.

Highlights:

- Deposit is in mining-friendly Manitoba, Canada and adjacent to a power line, rail line, and airport

- CIM compliant Measured & Indicated mineral resource of 20.8mt at 0.57% Ni, 0.30% Cu and (Wardrop Technical Report April 2011)

- Approximately 50% of the host rock remains unexplored

- Over 95% nickel recovery in the bioleach process indicated in Lynn Lake Prefeasibility Study by Wardrop in December 2007

- An exciting 2008 Disco Zone discovery, located 1.5km away from the outlined resource, which includes drillhole intercepts of 47 meters of 0.7% nickel (See July 7 , 2010 news release for full drill results)

- 2010 discovery of the Tango Zone, which includes drill hole intercepts of 17.3 meters of 0.6% nickel and 0.3% copper between historic mine level infrastructure (See December 6, 2010 news release for full drill results)

- 2012 bioleach optimization study indicated an operating temperature of 70°C with dedicated Cu and Ni Solvent Extraction Electrowinning circuits

Lynn Lake Nickel Resource:

| Tonnes (t) | Ni (%) | Cu (%) | |

|---|---|---|---|

| Measured | 0.92 Million | 0.76 | 0.36 |

| Indicated | 19.85 Million | 0.56 | 0.30 |

| Total M&I | 20.78 Million | 0.57 | 0.30 |

| Inferred | 7.33 Million | 0.51 | 0.28 |

Based on mineral resource estimated at 0.4% NiEq cut-off

| Metal | Measured | Indicated | Inferred |

|---|---|---|---|

| Nickel (Ni) | 0.02 Billion lbs. | 0.25 Billion lbs. | 0.08 Billion lbs. |

| Copper (Cu) | 0.01 Billion lbs. | 0.13 Billion lbs. | 0.05 Billion lbs. |

The resource estimate is based on a 0.4% NiEq cut-off with 100% metals recoveries. The Lynn Lake mineral resource is discussed in the April 2011 NI 43-101 Technical Report by Wardrop Engineering, authored by Todd McCracken, P. Geo. of Wardrop Engineering Inc., a Tetra Tech Company, who meets the Ni 43 101 requirements regarding Independent Qualified Persons.

Disco Zone

Discovered in April 2008, drilling at the Disco Zone outlined a shallow, arcuate body with a total length of 100m and an average width of 16m with mineralization intersected to a depth of 274m. The morphology, occurrence, and mineralization of the Disco deposit is characteristic of the morphology of the orebodies mined at Lynn Lake during its historic operations.

Discovered in April 2008, drilling at the Disco Zone outlined a shallow, arcuate body with a total length of 100m and an average width of 16m with mineralization intersected to a depth of 274m. The morphology, occurrence, and mineralization of the Disco deposit is characteristic of the morphology of the orebodies mined at Lynn Lake during its historic operations.

Significant mineralization was intercepted in 15 drillholes; most notably, hole LLN-043 which intercepted 47.1 meters of 0.7% nickel, 0.5% copper 0.02% cobalt, and LLN-015 which intercepted 18 meters of 1.5% nickel, 0.7% copper and 0.04% cobalt.

The Disco deposit is separate from the Lynn Lake resource and remains open to the southwest and at depth. Prophecy had an ‘induced polarization’ (IP) geophysical survey completed in and around the Disco Zone. In addition to characterizing mineralization within this zone, the geophysical survey also highlighted 10 similar targets.

The 3D modeling of the Disco Zone that confirmed ‘open-areas’ in proximity to the Disco Zone both at depth and to the southeast also confirmed the presence of a structure that controls the mineralization and trends to the south-southwest direction. Historically, the Lynn Lake mineralization was associated with a different, south-southeast trending structure. It is believed that this new structure is related to the historical structure and offers a similar exploration potential along its main trend. The main trend of this newly discovered controlling structure represents potential for future discovery of near-surface mineralization. The combined results of the 3D modeling and IP survey demonstrate the exploration potential at Lynn Lake.

Tango Zone

In 2010, drilling conducted to test several induced polarization (“IP”) targets derived from geophysical surveying led to the discovery of the Tango Zone. Tango has a broader geophysical signature and greater vertical extent than the Disco Zone. Three 2010 holes delineated a minimum total vertical extent of approximately 180 meters. The mineralized zone has an average thickness of 13.8 meters true-thickness; the best intersection being PCY10-02, which encountered 17.3 meters of 0.6% nickel, and 0.3% copper.

The IP anomaly at Tango extends downward below a depth of 600 meters from surface and then extends southwards for another 380 meters, which remains untested. The Tango zone could represent a third faulted block of mineralization and further exploration is warranted.

Bioleach Mineral Processing

Mintek, South Africa, issued the final report on November 11, 2011 that discussed metallurgical results related to the amenability of Lynn Lake mineralization to a bioleach process. The report was overseen by Andy Carter, Manager of Metallurgical Engineering for Tetra Tech Inc. The report concluded that there was good potential to achieve nickel extractions in excess of 95% using a moderate grind and leach temperature where high copper recoveries would generally require finer grinding and higher temperatures.

During 2012 Mintek, South Africa, completed a review of a bulk concentrate approach followed by optimizing the bioleach process to recovery nickel. The solvent extraction and electrowinning (SXEW) would be utilized to produce copper cathode, however, the recovery of nickel could proceed with one of three approaches; SXEW, or as a mixed hydroxide precipitate (MHP) or as a sulfide precipitate (SP). The firm concluded that the optimal approach was the production of nickel in cathode form (SXEW) with bioleaching at 70°C.

Photo Gallery